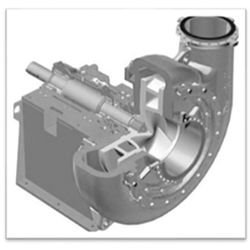

SL Engineers is a slurry pump manufacturer. We have 35 years experience. Our company set scientific research and development and manufacturing, we provide pump design, casting, machining, assembly, as well as heat treatment, physical and chemical analysis complete scientific research for new products, new materials, as well as first-class product quality to provide a strong support.

Slurry pump can meet the requirement of mining, metallurgy, non-ferrous metals, power plant ash removal, power plant desulfurization and other industries containing solid particles of material transport. SL Engineers pump industry with its good reputation and quality. With its positive pioneering spirit, customer demand as the focus, to ensure the perfect service quality, and continuous development, innovation.

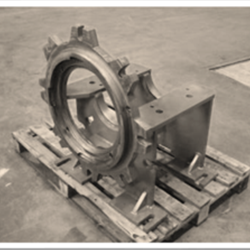

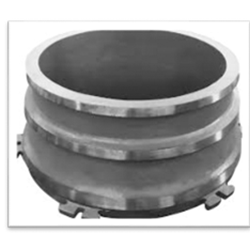

SLURRY PUMP REPLACEMENT PARTS

SL Engineer manufacture and supply various make & Model slurry pump components with interchangeability to the existing pumps. We provide pump components in Ni-Hard, High Chrome alloys to ensure durable performance with minimum wear and tear.

- Inner Casing

- Outer Casing

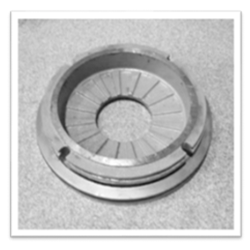

- Volute Liner

- Bearing Housing

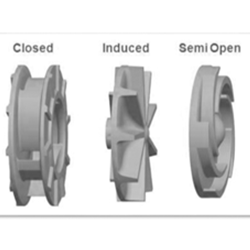

- Impeller

- Expeller

- Liner suction side/engine side

- Wear plate suction side/ bracket side

- Stuffing box

- Shaft

- Shaft sleeve

- Bell Suction/Engine Side

- Suction / Discharge adapter

- End Cover

- Top Cover

- Laybrinth

- Expeller Housing

- Lantern ring

- Suction cover

- Insert

Unparalleled range of premium wears parts for Mining & Aggregate

SL Engineers offers an unparalleled range of premium wear parts that are renowned worldwide for their superior precision and quality.

Some of our offerings include:

SL Engineers is India’s leading wear parts manufacturer and is solving the ever-widening challenges of Stone Crushing, Mining, Quarrying, Aggregate and Shredding industry

we produce high-quality crusher wear parts that are designed for numerous industrial applications. Whether they’re put to use in recycling plants, the aggregates industry or in the mining sector, our crusher wear parts offer durability, crushing efficiency and sustainability. Thanks to our reduced breakage risks compared to inferior products, our parts will offer a consistent return on investment, something that many of our valued customers would readily agree with. Therefore, anyone seeking crusher wear parts from the market leader in the design and manufacturing of these important aggregates, recycling, mining and cement industry components should find out exactly why so many in the sector consider SL Engineers to be the best.

SL Engineers range of crusher wear parts is designed to cater to a wide range of applications across various industries. Our wear parts are compatible with numerous crusher types, including impact, cone, and gyratory crushers. By offering a comprehensive range of crusher wear parts in our product range, we ensure that our customers can find solutions tailored to their unique requirements and operational environments. that our crusher wears parts are suitable for applications in primary, secondary, and tertiary crushing. They are renowned around the world for providing consistent performance in diverse conditions. For example, they are designed to handle various materials, including limestone, granite, basalt, ores and recycled concrete, to name but a few examples. This adaptability enables our customers to achieve their desired output size and shape, improving overall productivity and efficiency when they invest in our crusher wears parts. SL Engineers wear parts also cater to specialized applications, particularly our crushers WEAR PARTS to be used in the production of high-quality aggregates and sand and ores. Our expertise extends to the aggregates and recycling industries as well as to the mining and cement industries, enabling us to provide crusher wear parts that offer excellent wear life and performance, regardless of the application or particular industrial niche.

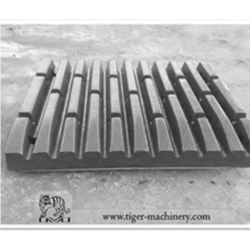

Jaw Crushers

- Jaw Plate – Fixed Jaw Plate & Movable Jaw Plate

- Side Plate – Cheek Plate Upper & Cheek Plate Lower

- Wedge

Cone & Gyratory Crushers

- Concave

- Mantle

- Spider cap

- Gyratory Concave